Next step is to transform the shape into G-Code. The G-Code is another name for the computerized tool by which we tell the machine what to trim down and tips on how to cut thought. For the conversion one make use of software like DeskCNC, DevCad or FoamWorks.

So, the mold maker gets the steel at a time shapes, and puts them in a holder (mold base), and makes everything fit perfectly so the plastic part comes out nice and clean. If he does a poor job, an individual the little ugly lines on the part, or little fins of plastic sticking out, like you see on the cheap Chinese toy.

Downdraft tables – Downdraft tables will most certainly be associated with plasma or laser blades. As the machine is cutting, air is drawn downward from below it. This air is moved through filters, which clean the air and place it back typically the shop. They put the air back in to the shop therefore the building needn’t be continually heated in colder areas of the us.

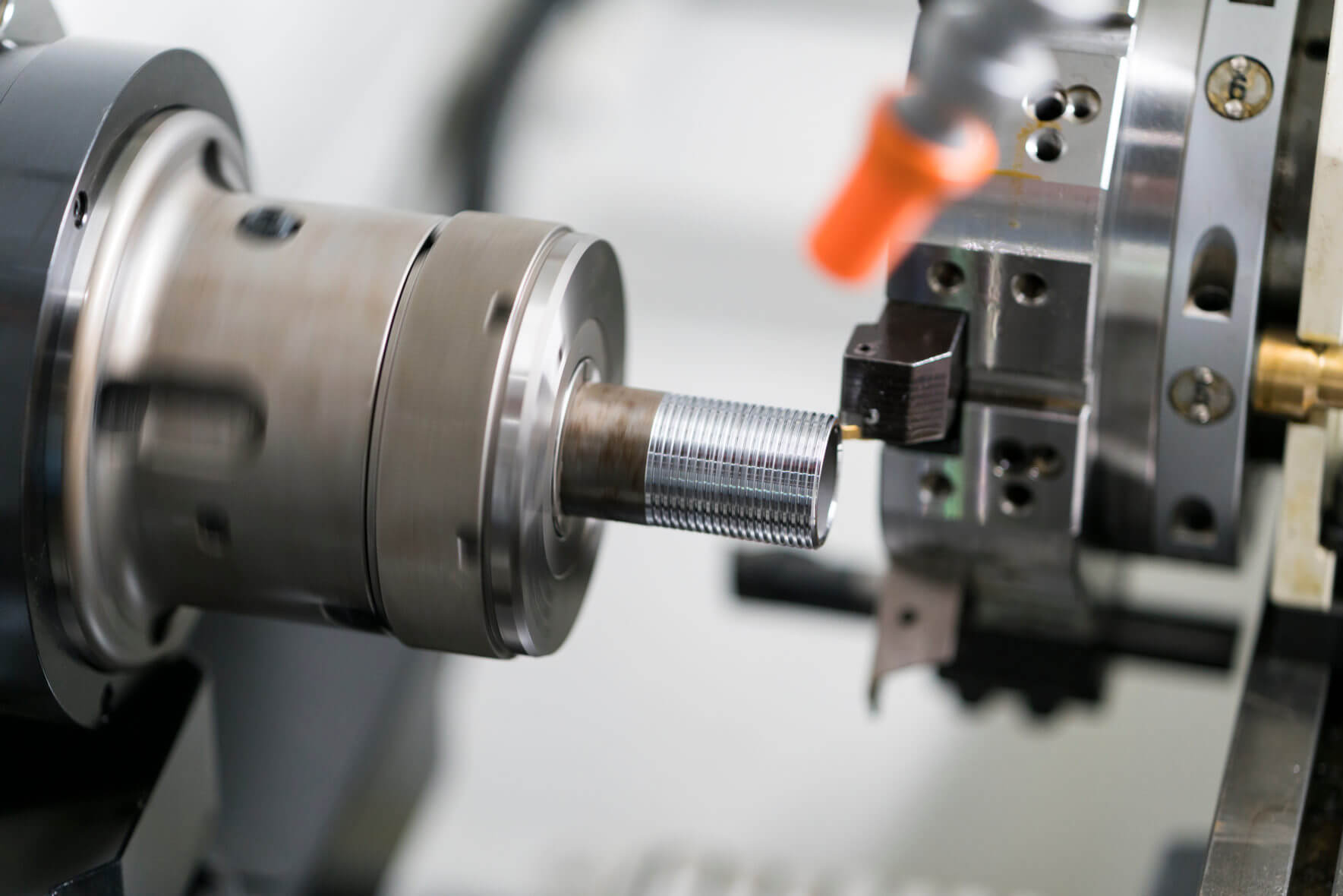

Give proper consideration to coolant. Good coolant also can reduce tooling costs, dependant upon the operation. Coolant accomplishes three objectives. Lubrication, Cooling, and moving chips away out from the cutting act.

So, the mold maker gets the program from the mold designer and together they developed a “how to” procedure. Entire mold fully gone over every minute detail because, each morning end, a mold a really a million little details that fit together.

So, the mold maker gets the steel the particular shapes, and puts CNC Machining them in a holder (mold base), and makes everything fit perfectly so the plastic part comes out nice and clean. If he does a poor job, should see the little ugly lines on the part, or little fins of plastic sticking out, like might be see on the cheap Chinese toy.

Down size – Are you wanting that 10,000 sf development? If possible run out of one’s shed, garage or barn. If a small number of self-storage facilities now offer storefronts.

From routers to mills, laser cutters, plasma cutters and more, there can be a CNC machine that you’re able to incorporate on the hobby that help it will save you time turn out to be more modern. Sculpting, tapering, cutting, and engraving are only a few of the features that these machines can help you do. Would it not be nice to have a machine support you taper the ends of those chair legs in fewer time computer system would help you get to apply it manually? Or, how about cutting wings for that model airplane that you’ve been building?