Pallet wrapping, a necessary component of any efficient supply chain, has traditionally been a labor-intensive and time-consuming process. However, thanks to the incredible advancements in technology, businesses can now harness the power of automated machines to streamline their pallet wrapping operations. Enter the pallet wrapping machine, a game-changing innovation that offers a range of benefits to companies of all sizes.

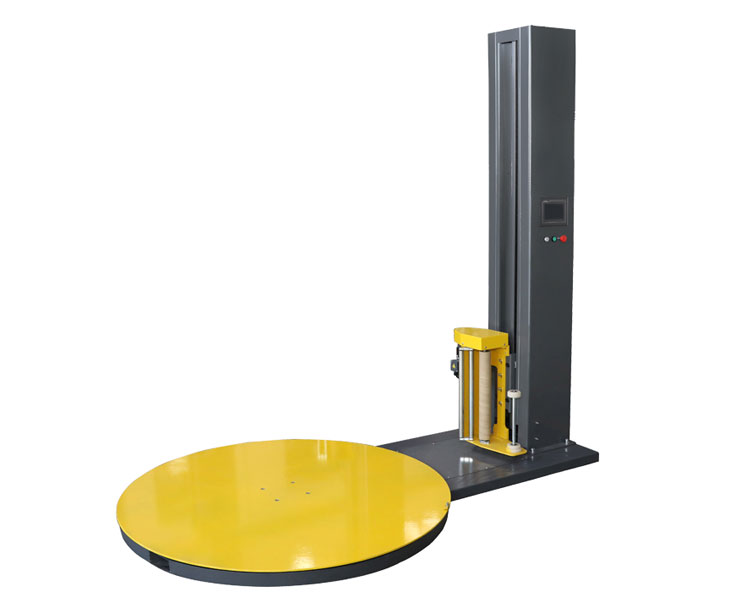

Designed to simplify the entire pallet wrapping process, a pallet wrapping machine, also known as a pallet wrapper or stretch wrap machine, is a marvel of modern engineering. By automating the wrapping process, these machines eliminate the need for manual labor, reducing the risk of injuries and increasing overall efficiency. With just a few simple steps, businesses can now achieve consistent, tight, and secure wraps with ease. The stretch wrap used by these machines provides reliable protection and stability, ensuring that products remain intact and undamaged during transit or storage. With the ability to handle various pallet sizes and weights, pallet wrapping machines offer unparalleled versatility, allowing businesses to adapt to changing requirements effortlessly.

Gone are the days of grappling with rolls of stretch wrap, struggling to achieve uniform tension, and wasting valuable time and resources. Pallet wrapping machines empower businesses to optimize their packaging processes, ultimately improving productivity and reducing costs. Whether in a warehouse, distribution center, or manufacturing facility, utilizing a pallet wrapping machine can revolutionize the way organizations approach palletizing and shipping their products.

In the next sections, we will dive deeper into the key features and benefits of pallet wrapping machines, exploring their different types, their operation processes, and how they can enhance your business’s efficiency and profitability. So, join us as we unveil the power of these remarkable automated machines and discover a new era of effortless pallet wrapping.

Advantages of Pallet Wrapping Machines

Pallet wrapping machines offer a range of advantages that make them an indispensable tool in the logistics industry. From increasing efficiency to enhancing product protection, these automated machines have revolutionized the process of pallet wrapping. Let’s take a closer look at some of the key benefits they bring.

Improved Efficiency: Pallet wrapping machines streamline the entire wrapping process, saving valuable time and effort. With their automated features, they can wrap pallets at a much faster rate compared to manual methods. This increased efficiency not only boosts productivity but also allows workers to focus on other important tasks, leading to overall operational optimization.

Stretch Wrap Machine

Consistent and Secure Wrapping: One of the major advantages of using a pallet wrapping machine is the ability to achieve a consistent and secure wrap every time. These machines are equipped with advanced stretch wrapping technology that ensures the stretch film is evenly distributed and tightly secured around the pallet. This eliminates the risk of loose or unstable loads during transportation, preventing damage and enhancing overall load stability.

Versatility and Adaptability: Pallet wrapping machines are designed to accommodate various load sizes and shapes, making them highly versatile. They can easily accommodate different pallet heights and dimensions, allowing for seamless wrapping of different types of products. Additionally, many machines are equipped with customizable settings, enabling users to adjust film tension and other parameters based on specific wrapping requirements.

In the next section, we will explore additional benefits and features of pallet wrapping machines, delving deeper into how they contribute to a more efficient and cost-effective supply chain.

Choosing the Right Pallet Wrapper

When it comes to pallet wrapping machines, finding the right one for your specific needs is crucial. With a wide range of options available in the market, it’s important to consider various factors before making your decision.

Firstly, determine the size and weight of your pallets. Different pallet wrappers have different weight and size capacities, so ensure that the machine you choose can handle your specific requirements. Consider the maximum load weight and dimension specifications provided by the manufacturer to ensure compatibility.

Secondly, think about the level of automation you require. Some pallet wrappers offer fully automated operations, while others may require manual intervention. Automated machines can save time and effort by efficiently wrapping multiple pallets without constant supervision. However, if you have smaller quantities or prefer a more hands-on approach, a semi-automated or manual pallet wrapper may be more suitable.

Lastly, consider the type of stretch wrap film you plan to use. Pallet wrappers are designed to work with different types of stretch film, such as pre-stretched film or traditional stretch film. Ensure that the machine you choose is compatible with the specific film type you intend to utilize. Additionally, take note of the film width and length requirements as specified by the manufacturer.

By carefully considering these factors, you can choose the right pallet wrapper that aligns with your pallet wrapping needs. Whether you prioritize efficiency, load capacity, or compatibility with specific stretch films, selecting the appropriate machine will enhance your pallet wrapping process and streamline your operations.

Tips for Efficient Pallet Wrapping

Proper Load Placement:

When using a pallet wrapping machine, it is crucial to carefully position your load on the pallet. Placing the heaviest items at the bottom and distributing the weight evenly will ensure stability during the wrapping process. This prevents any shifting or toppling over, reducing the chances of damage during transportation.Optimal Film Tension:

Achieving the right tension on the stretch wrap is essential for effective pallet wrapping. If the film is too loose, it might not provide sufficient support and protection. On the other hand, overtightening the film can lead to excessive pressure on the goods, potentially causing damage. Adjust the tension settings on the pallet wrapping machine according to the load requirements and consider using pre-stretch mechanisms for even distribution.Proper Overlap and Film Coverage:

To ensure the pallet is adequately secured and protected, it is essential to have proper overlap and film coverage. Make sure the stretch wrap overlaps each previous layer by at least 50% to provide strong, consistent coverage. Cover all corners and edges of the load to prevent any exposed areas that may be vulnerable to damage or tampering.

By following these tips, you can maximize the efficiency of your pallet wrapping process, ensuring that your goods reach their destination safely and securely.