In the world of valves and controls, precision and efficiency are key elements in optimizing industrial processes. Valworx, a respected ISO 9001-certified supplier, stands out for its dedication to providing high-quality actuated valves and controls to various markets. With a vast selection of automated valve assemblies meticulously built, tested, and shipped the same day, Valworx ensures that industrial, institutional, and government sectors receive reliable products tailored to their specific needs.

Types of Actuated Valves

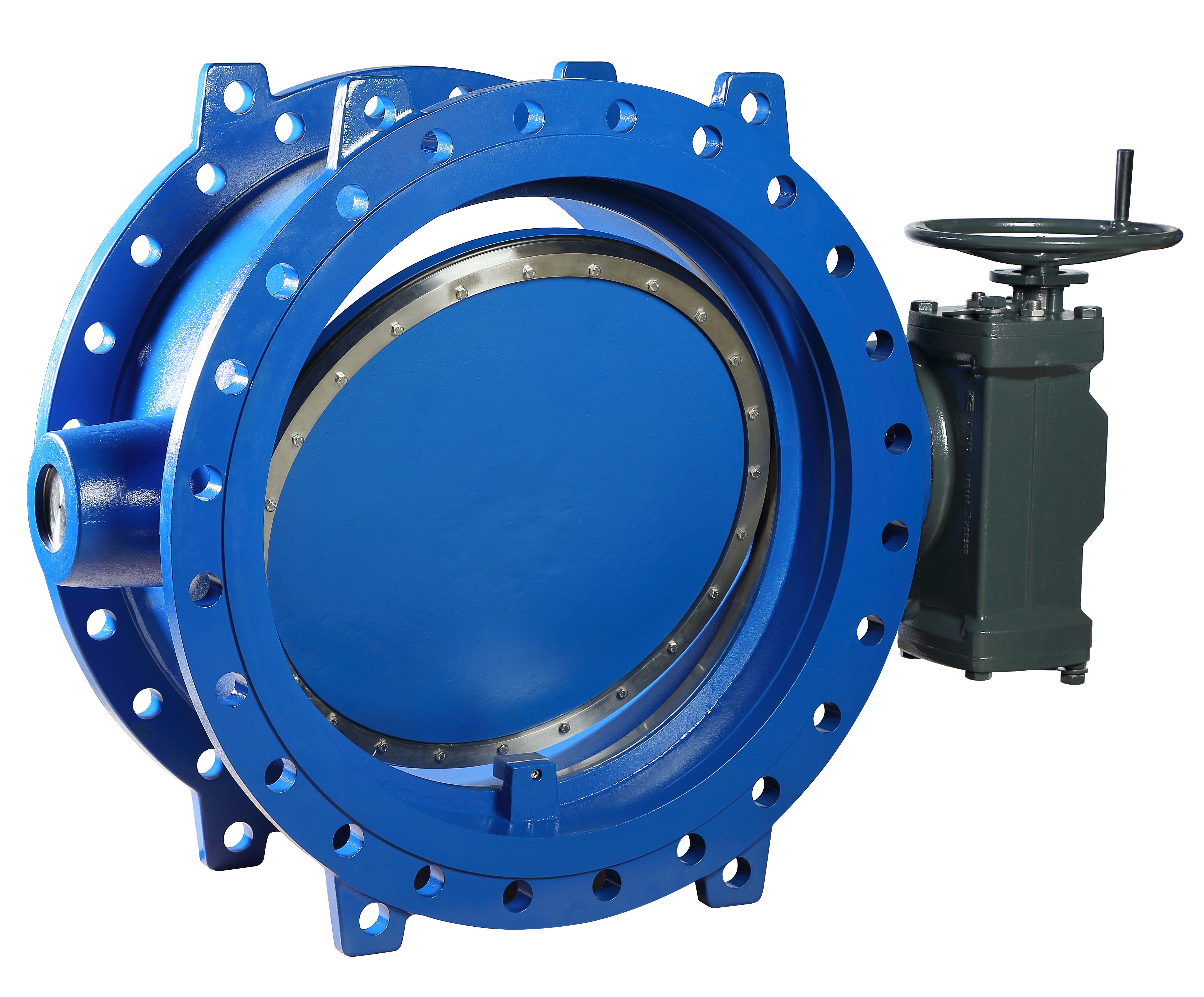

Actuated valves come in a variety of types, each designed for specific applications. One common type is the ball valve, which offers quick quarter-turn operation, making it ideal for on/off applications. Another widely used type is the butterfly valve, known for its low-pressure drop and cost-effectiveness. Gate valves are also popular for their tight sealing capabilities, making them suitable for high-pressure systems.

When it comes to actuated valves, globe valves are often chosen for their precise flow control capabilities. These valves regulate flow by moving a plug against the flow stream. Diaphragm valves, on the other hand, are well-suited for applications requiring a high level of cleanliness, as the valve design prevents contamination. Pinch valves are versatile and can handle abrasive and corrosive materials, making them a reliable choice for challenging environments.

Consider the specific requirements of your system when selecting actuated valves. Understanding the different types available can help you choose the most suitable valve for your application. Whether it’s for flow control, shut-off, or throttling, there is a wide range of actuated valves to meet your needs.

Benefits of Using Valworx Products

Valworx products provide unmatched reliability and durability in various industrial applications. With Valworx’s ISO 9001 certification, customers can trust the quality and performance of each actuated valve and control. The seamless integration of automation technology ensures precise and efficient operation, contributing to enhanced productivity and operational efficiency.

By choosing Valworx products, customers benefit from the convenience of having access to a wide range of automated valve assemblies that are built, tested, and shipped within the same day. This streamlined process not only saves time but also minimizes downtime for industrial, institutional, and government markets. The quick turnaround time reflects Valworx’s commitment to customer satisfaction and operational excellence.

Wafer butterfly valve with EPDM seat

Furthermore, Valworx’s commitment to providing prompt and reliable service sets them apart as a trusted supplier of actuated valves and controls. The dedicated support team is readily available to address any inquiries or concerns, offering personalized solutions to meet specific project requirements. With Valworx products, customers can expect unparalleled support alongside superior quality and performance.

Tips for Proper Valve Maintenance

First and foremost, regular inspection of valves is crucial to ensure optimal performance. Look out for any signs of leaks, corrosion, or buildup that may indicate a potential issue. Maintaining a clean and well-functioning valve can significantly extend its lifespan and reduce the risk of costly repairs.

In addition to visual inspections, it is important to follow the manufacturer’s guidelines for routine maintenance. This may include lubricating moving parts, replacing worn out seals, or adjusting valve settings as needed. By staying proactive with maintenance tasks, you can avoid unexpected downtime and ensure that your valves operate smoothly.

Lastly, establish a maintenance schedule and stick to it. Set reminders for routine checks and servicing to prevent any neglect or oversight. By staying organized and proactive with valve maintenance, you can maximize the efficiency and reliability of your valve systems in the long run.