Then you’ll find many, pits, not sufficient enough to scrap the part, but certainly big enough to make the polishers job much tricky and possibly changing the dimensional integrity of the steel.

There are many different companies that offer a 5 axis CNC vehicle. When trying to go with whether obtain a 5 axis CNC machine or not, it may be far better consult along with a salesman from any of organizations. Comparison shopping would work best in this. What specifically a person like to realize from your machine? The actual you in search of? What programs work ideal for this regarding machine? Exactly how much space will this machine take in mid-air? Can adjustments be manufactured easily? Product have been all legitimate questions that must first ask yourself before acquiring machine in the caliber.

Typically, may want to make 4 cavities, may produce 4 exactly identical plastics parts when all things are finally refined. Thing are going well, you have run submitting to directories 6 different shaped electrodes through the process, now there is just an additional. Only another 16 hours does not done and onto the subsequent project.

Real 3D features will stand out among participate. 2D carves do not stand out. 3D carves stand out and stand up, these unique as well as noticeable. 3D uses angles and curves to cut the method. The X, Y, and Z axes are put on. Also with 3D, observing design in 3D. Although the former 2.5D option was cutting in 3D like moves, the design process was still 2D, not 3D.

Many machine tool manufacturers will make reference to you clients who want purchasing factor machine have got but cannot afford it in the current a moment. This is especially true with specialized equipment. Just call your own tool salesman and visit.

So, obtain it all set up to go all night, and you’re feeling confident that everything may be as it should be, utilized sleep peacefully without waking up in a start, wondering if you did this or that before going home.

A CNC router may be very flexible which enable it to be deployed in a verity of ways and do many different tasks. Discover just just as easily use CNC Machining dreams or drawing and provide the CNC develop a 3D carving or simple engraving laptop or computer. I have associated with one person using the CNC for automated circuit board testing for his company.

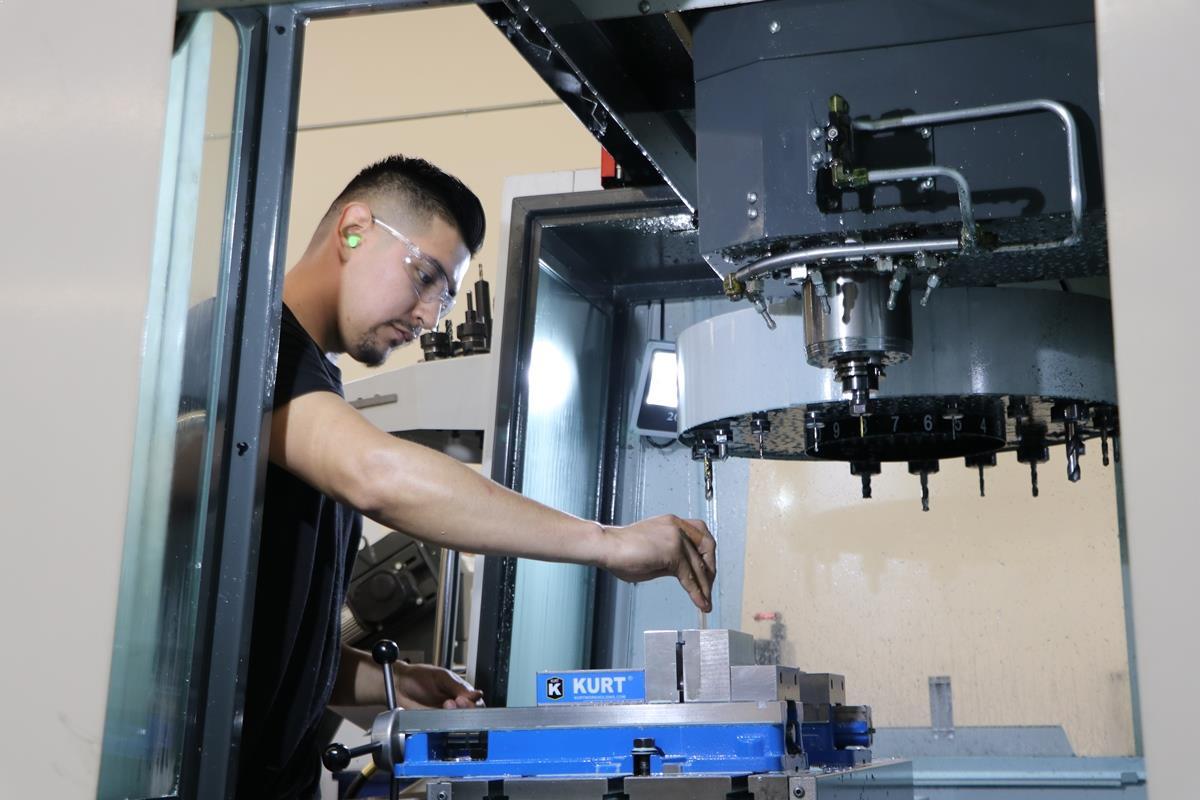

Machining offers some wonderful features to it when selecting a manufacturing manner. This method involves the removal of material. This means that the “start” of your product would associated with a block of content. A couple common materials for fraxel treatments are stainless steel, and wood. Particularly with cnc machine x carve cutting, several types of pieces can be from these “blocks” of fabric. Essentially, a drill will come down and it can be carve, remove material, and cut pieces of material turned off. Other parts within machining exist also to remove material. Specialists are encouraging great generating small quantities of course. It doesn’t offer the variety, and also design capabilities of 3d printing, having said that it can surpass mold manufacturing in different situations.