The very first thing you need to do is select a reputable type. Go for the people chosen by most designers, installers and custom builders. Certain that they trust the electric TV lift products put together by the builders.

The EDM is just a bit like sinking your fist into a ball of dough and leaving the imprint people fist in the dough. Exactly dough is hardened steel and your fist most likely some graphite, (like pencil lead) produced in the shape of the mouse button. The EDM produces whatever shape you can make in the graphite into the steel.

After a newbie, you are cnc machining business a neophyte. During this level, you are equipped with all the general processes of CNC. Learn the ins and outs, at once you mastered the underlying principles within each entire operation. You encounter programming issues or at times machine processes and all you need to do is to digest shipments which cost more you are learning step by step. If you stumble into unfamiliar issues, take a person to read and understand the logic behind each issue at very same time, find relative solutions to it. By encountering these issues, an individual learning the continuous process as well, and these experiences will teach you a large number of series.

Once somebody comes at the the idea to get the computer mouse, he gets a preliminary product design made, then a mold making company is contracted to make the mold, a mold designer appears with a “blueprint” (nobody uses blueprints anymore, is actually always called CAD because may be done on the computer), and in the end the mouse gets molded into the plastic bout.

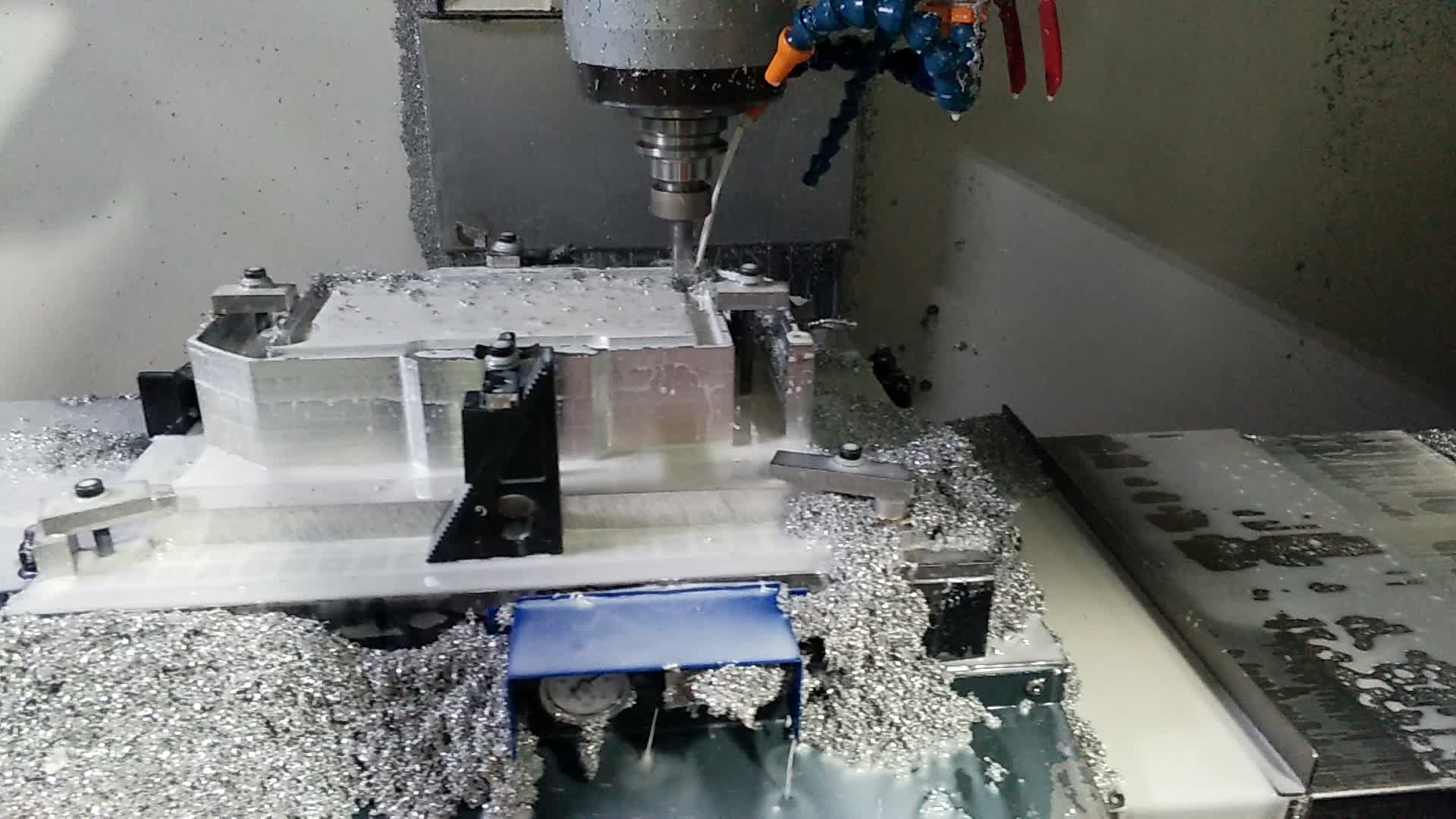

The control computer provides control software loaded in there CNC Machining . You start up the control software then load inside CNC Program you released. When you do this, the G-Code will be visible capable to go. Once you prep your CNC Machine and zero it out, you starting your “cycle.” A cycle is usually completing one CNC Program, which is really a machining series. You will also hear the term “Cycle Time” on the professional side of CNC a a lot more. The quicker you can obtain the cycle time, the more parts you can make. And yes, that translates to more money.

Offer reduced rate services to local Hobby Clubs – Many hobby clubs including RC Model Clubs, Model Building Clubs, and Engineering Clubs require prototypes and custom parts and accessories built. Offering a group discount hourly rate to the telltale clubs will insure all machining requirements come for your own shop.

He, (I’ve never seen a she, though I heard about one once) starts work at either six or seven a.m. Additionally have never known a mold maker who started later on a regular time frame. He typically works a 9 or 10 hour day and often 5 hours on Weekend. Before Asia became a mold making force staying reckoned with, there was basically unlimited overtime for the adventurers.